Butterfly valves are critical components in industrial piping systems, and their performance heavily relies on proper bolting configurations. This guide provides a detailed butterfly valve bolt chart for flange, wafer, stainless steel, and carbon steel valves. Whether you’re an engineer, procurement specialist, or maintenance professional, understanding bolt specifications ensures safe and efficient valve operation.

Why Bolt Charts Matter for Butterfly Valves

Bolting is the backbone of valve assembly integrity. Incorrect bolt size, material, or torque can lead to leaks, valve failure, or even system downtime. A bolt chart for flanges or butterfly valves standardizes:

- Bolt dimensions (diameter, length, thread type).

- Material compatibility (stainless steel, carbon steel).

- Torque values to achieve optimal sealing.

For flange butterfly valves and wafer butterfly valves, bolt charts vary based on valve size, pressure rating, and flange standards (ANSI, DIN, JIS).

Flange Butterfly Valve Bolt Chart

ANSI Flange Bolt Specifications

ANSI B16.5 flanges are widely used in North America. Below is a simplified flange bolt chart for Class 150 and Class 300 butterfly valves:

| Valve Size (inches) | Bolt Quantity | Bolt Diameter (inches) | Bolt Length (inches) |

| 2″ | 4 | 0.5″ | 2.5″ |

| 6″ | 8 | 0.75″ | 3.5″ |

| 12″ | 12 | 1″ | 4.5″ |

Material Notes:

- Stainless steel butterfly valves often use ASTM A193 B8 bolts for corrosion resistance.

- Carbon steel butterfly valves pair with ASTM A307 bolts for high-strength applications.

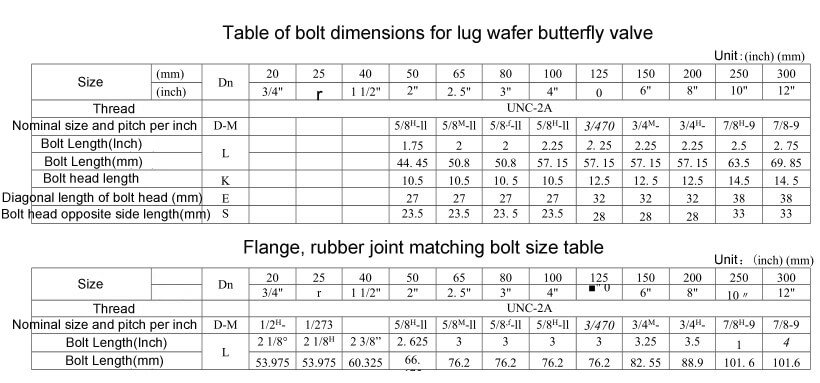

Wafer Butterfly Valve Bolt Chart

Wafer butterfly valves are lightweight and rely on flange bolts for compression. Their bolt chart focuses on:

- Bolt length: Must span the valve body and flanges.

- Spacer sleeves: Often required to prevent over-tightening.

| Valve Size (inches) | Bolt Length (inches) | Torque (lb-ft) |

| 4″ | 3.0″ | 45–50 |

| 10″ | 5.5″ | 90–100 |

| 16″ | 7.0″ | 150–170 |

Tip: Always confirm bolt length with the butterfly valve manufacturer to avoid mismatches.

Bolt Material Selection: Stainless Steel vs. Carbon Steel

Stainless Steel Butterfly Valve Bolts

- Grades: ASTM A193 B8 (304/316 SS) for high corrosion resistance.

- Applications: Chemical, marine, or food processing industries.

- Torque: Lower torque required compared to carbon steel.

Carbon Steel Butterfly Valve Bolts

- Grades: ASTM A307 or A325 for high tensile strength.

- Applications: Oil, gas, and high-temperature systems.

- Coating: Galvanized or zinc-plated to prevent rust.

How to Choose a Reliable Butterfly Valve Manufacturer in China

China dominates global valve production, but quality varies. Key factors when selecting a China butterfly valve manufacturer:

1. Certifications: ISO 9001, API 609, CE.

2. Material Traceability: Mill test reports for stainless/carbon steel.

3. Custom Bolt Charts: Ability to provide valve-specific bolt specifications.

Top Markets:

- Wafer butterfly valves for HVAC systems.

- Flange butterfly valves for water treatment plants.

FAQs About Butterfly Valve Bolt Charts

Can I reuse bolts during valve maintenance

Reusing bolts is risky due to thread wear. Always consult the bolt chart for flanges and replace bolts if torque values drop below specifications.

What if my bolt chart doesn’t match the valve size

Contact the butterfly valve manufacturer for clarification. Mismatched bolts compromise seal integrity.

Conclusion

A precise butterfly valve bolt chart is non-negotiable for system reliability. Whether you’re working with stainless steel butterfly valves in corrosive environments or carbon steel butterfly valves in high-pressure systems, adhering to bolt specifications prevents costly failures. Partner with certified China butterfly valve manufacturers to ensure compliance with international standards and access tailored bolt charts for your application.

Post time: Apr-08-2025